State-of-the art testing methods for diagnostics and quality control

In addition to our excellent welding services, we also meet the highest quality standards with our on-site non-destructive testing (NDT). We use state-of-the-art testing methods to ensure high system availability and economy as part of our full-service package.

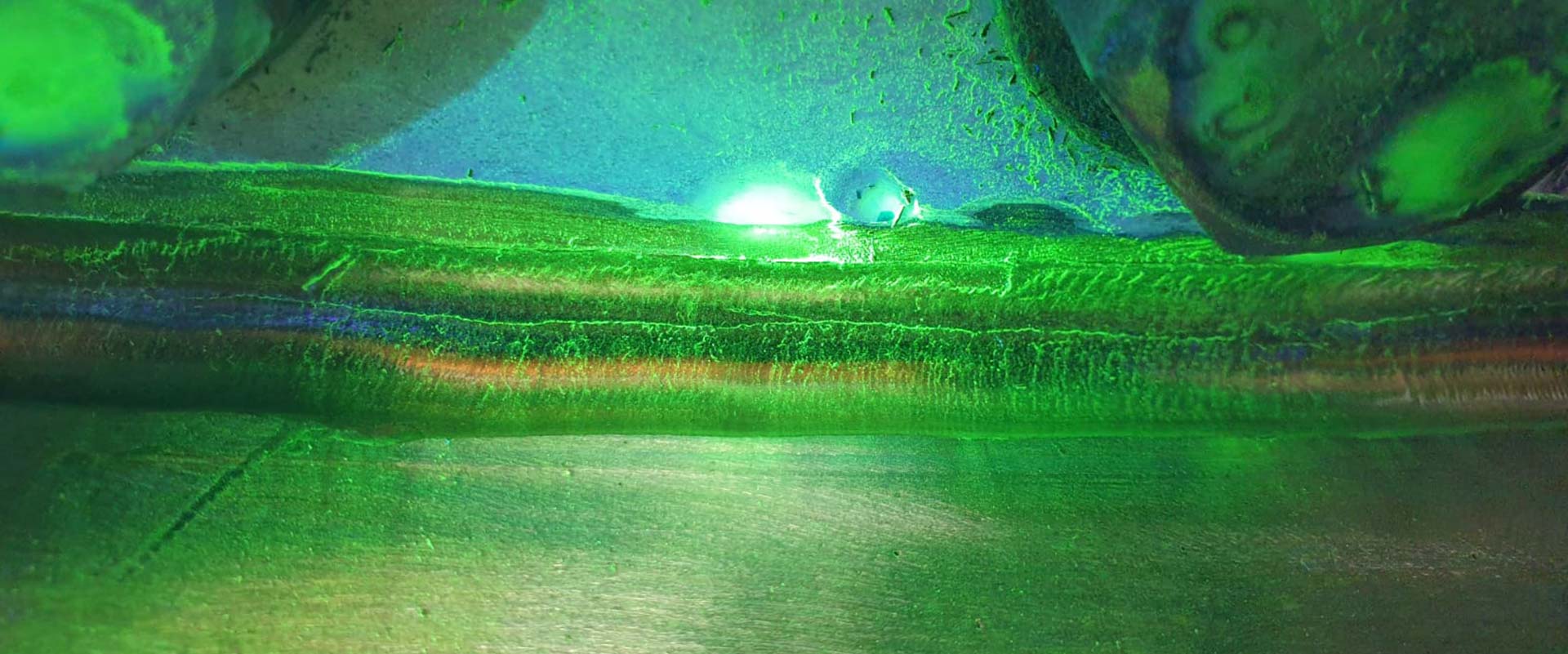

One of our standard procedures is magnetic particle testing (MT), which saves time and enables materials to be tested directly on site before, during and after welding work.

We also use other common testing methods to meet the relevant requirements.

Certificates

Various certificates for every assignment

As a certified welding company, we meet the DIN EN ISO 3834-2 and EXC 3 EN 1090-2 standards for welding supervisors, welding and testing personnel, and operational facilities and equipment. We are approved by insurance companies and other institutions, making us an important partner for high-quality welding work around the world.

Our welders are trained and examined on a regular basis – both within our company and at external training centers – so that they obtain the required qualifications and certifications.

We also implement DIN ISO 9712 for non-destructive testing (NDT) to detect any damage and ensure that our work has been carried out to a professional standard.

VRT Nord GmbH

Teichkoppel 32

D-24229 Dänischenhagen

Tel. +49 (0) 4349 913 380

info@vrt-nord.de